Bodor Laser

From concept to production, we deliver high-quality, scalable, and cost-effective solutions tailored to your business needs.

From concept to production, we deliver high-quality, scalable, and cost-effective solutions tailored to your business needs.

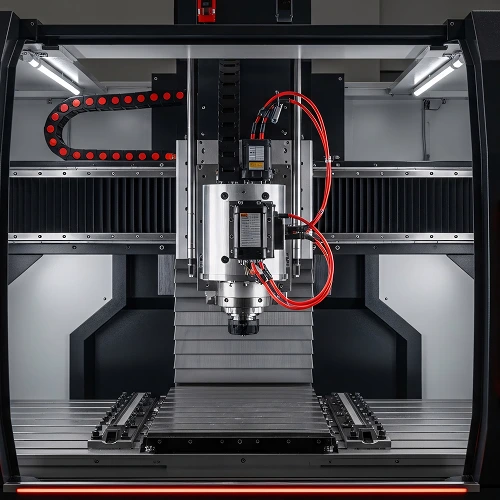

Faster than ever. Setting a new industry trend at an unrivaled pace.

Backed by cutting-edge laser technology, expert engineering, and a commitment to quality, we help businesses transform their manufacturing capabilities with confidence and speed. Whether it's cutting, welding, or marking, we're your trusted partner every step of the way.

Delivering consistent manufacturing excellence since day one.

Precision-crafted components delivered globally

Precision-built products delivered to clients across industries and continents.

After scanning the remaining material and importing its picture into the cutting system, our self-developed algorithm uses visual recognition to generate the remnants' contour with one click, allowing for the secondary layout and utilization of irregular scrap materials.

Self-developed servo-following sensors and path avoidance algorithms can accurately sense obstacles in real-time at 360° in the position changes of the tube edges, and plan the obstacle avoidance route in advance to reduce the risk of laser head collision significantly.

By utilizing closed-loop control, the system performs real-time detection and adjustment of air pressure, ensuring cutting consistency and achieving a "uniform quality" effect for batch processing.

Automatically replace the nozzle based on material type and thickness, ensuring safe and efficient operation.